Picking the right drain system is crucial for your business. This guide provides a detailed comparison of hub drains and floor drains, offering insights into hub drain installation, maintenance, material selection, and cost analysis to help you make informed decisions. Whether you’re a building manager, plumber, architect, or restaurant owner, this guide will help you choose the ideal drainage solution for your commercial property.

Understanding Commercial Drainage Systems

Choosing the right drainage system for your commercial building is a significant decision that directly impacts daily operations, sanitation, and long-term expenses. Discover the specific benefits of hub drains and how they compare to traditional floor drains to optimize your facility’s hygiene and efficiency.

What is a Hub Drain?

A hub drain serves as a central collection point for wastewater originating from multiple sources, such as sinks, toilets, and various plumbing fixtures within a commercial setting. Instead of each fixture draining independently, smaller pipes converge into the hub drain, streamlining your plumbing system and simplifying overall maintenance. This centralized approach allows hub drains to efficiently manage wastewater volumes common in commercial settings.

Hub Drains vs. Floor Drains: A Detailed Comparison

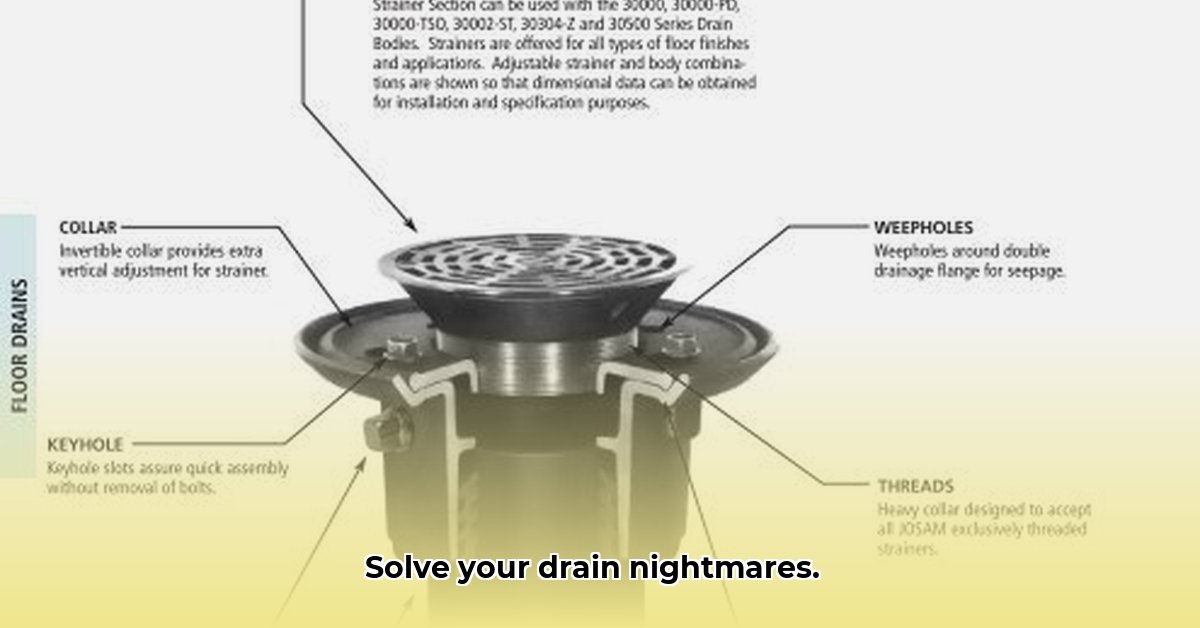

Compared to floor drains, hub drains offer a broader range of applications and design advantages. Floor drains are primarily designed to manage surface water in areas like showers, garages, and spill-prone zones, offering relatively simple installation and maintenance procedures. Hub drains, however, are engineered to handle wastewater from various sources, including indirect waste discharge from equipment.

Here’s a detailed comparison to highlight the key differences:

| Feature | Hub Drain | Floor Drain |

|---|---|---|

| Main Job | Collects wastewater from multiple fixtures and indirect waste lines into a central point | Collects surface water and direct spills from the floor area |

| Installation | More involved and complex, often requiring professional expertise | Relatively simple and straightforward, suitable for DIY in some applications |

| Maintenance | Generally easier access for maintenance due to centralized location; may require less frequent cleaning | Requires consistent cleaning of grates to prevent clogs and odor buildup |

| Versatility | Excellent; handles diverse wastewater sources including indirect waste | Limited to surface water drainage and direct spills |

| Upfront Cost | Typically higher initial investment due to materials and installation complexity | Lower initial cost, but potential for higher long-term maintenance expenses |

| Backflow Prevention | Can be designed with superior backflow prevention features | Standard designs may require additional backflow prevention measures |

| Typical Applications | Commercial kitchens, industrial facilities, hospitals, laboratories | Restrooms, showers, laundry rooms, garages, and areas prone to spills |

Factors to Consider When Choosing a Drain

Selecting between hub and floor drains depends heavily on your specific operational requirements and the environment where they will be installed. Carefully evaluate these key considerations before making a decision to ensure optimal performance and regulatory compliance:

- Wastewater Type: What type of wastewater will the drain need to handle (e.g., grease, chemicals, solids)?

- Drain Location: Where will the drain be located within the building (e.g., kitchen, restroom, processing plant)?

- Existing Plumbing: What is the building’s current plumbing structure and how easily can it be adapted?

- Maintenance Budget: What budget is allocated for ongoing maintenance and cleaning?

- Regulatory Compliance: Do any specific regulations or building codes apply to the drainage system in your area?

Installation and Maintenance for Hub Drain Systems

Proper hub drain installation is critical to ensure long-term functionality and prevent potential plumbing issues. Engaging experienced and certified plumbers is essential to avoid leaks, costly repairs, and future complications. A poorly installed system can lead to significant water damage, unsanitary conditions, and operational disruptions. Regular checkups and preventative maintenance are equally important:

- Leak Detection: Conduct routine inspections to check for any signs of water leakage around the drain and connecting pipes.

- Clog Prevention: Implement a preventative cleaning schedule to flush the system and remove any buildup that could lead to clogs.

- Damage Assessment: Regularly inspect the drain body and connecting pipes for signs of corrosion, cracks, or physical damage.

Choosing Durable Materials for Hub Drains

The material selection for hub and floor drains directly impacts their lifespan, performance, and resistance to corrosion and bacterial growth. Stainless steel is a popular choice for both types of drains due to its inherent durability and corrosion resistance. However, different grades of stainless steel offer varying levels of protection, making it crucial to select the appropriate grade for your specific application:

- Grade 304 Stainless Steel: Offers good corrosion resistance and is suitable for general-purpose applications.

- Grade 316 Stainless Steel: Contains molybdenum, which enhances its resistance to chlorides and other corrosive elements, making it ideal for more demanding environments such as food processing plants and coastal facilities.

Understanding the distinct properties of each steel grade ensures you select the most appropriate material to maximize the longevity and reliability of your drainage system.

Risk Assessment and Mitigation Strategies

Drainage system problems can cause disruptions ranging from minor inconveniences to severe operational shutdowns. By carefully understanding the inherent differences between hub and floor drains, and by proactively implementing risk mitigation strategies, you can make an informed decision that serves your commercial space effectively for many years to come.

| Risk Category | Likelihood | Severity | Mitigation Strategies |

|---|---|---|---|

| Complex Hub Drain Installation | Moderate | Moderate | Employ experienced and certified plumbing professionals; consider using pre-fabricated hub drain units to simplify installation and reduce potential errors. |

| Hub Drain Corrosion | Low | High | Select the appropriate grade of stainless steel based on environmental conditions (e.g., 316 for high-chloride environments); implement a regular inspection and maintenance program. |

| Floor Drain Clogging | High | Moderate | Implement a frequent cleaning schedule for grates and drain lines; select appropriately sized grates to prevent large debris from entering the system. |

| Floor Drain Slip-and-Fall Hazards | High | High | Ensure proper floor slope towards the drain to prevent standing water; utilize non-slip grates to provide enhanced traction and reduce the risk of slips and falls. |

| System Backups | Moderate | High | Install backflow preventers; perform routine inspections and maintenance to prevent blockages. |

| Regulatory Non-Compliance | Low | High | Stay up-to-date with local plumbing codes and regulations; ensure that all drain installations meet or exceed the mandated requirements, and maintain detailed records of inspections. |

Comparing Hub and Floor Drain Maintenance Costs for Commercial Kitchens

Selecting the right drainage solution for a commercial kitchen not only ensures optimal hygiene and sanitation but also minimizes operational costs, which can significantly impact your business’s profitability. Making an informed choice requires understanding the long-term expenses associated with each drainage option.

Understanding the Differences

Hub drains offer superior backflow prevention due to their indirect connection to the sewer system, which is vital in commercial kitchens to protect against contamination of food preparation surfaces and equipment. Floor drains offer a more direct drainage route, which may not provide the same level of backflow protection. This makes hub drains a more sophisticated and safer option for commercial kitchens due to their multi-stage filtration and enhanced backflow prevention capabilities.

Maintenance Cost Analysis

Hub drains, due to their design and functionality, often require less frequent maintenance compared to floor drains. Their raised inlets minimize the entry of solids and debris, reducing the likelihood of clogs. Floor drains, on the other hand, are more susceptible to clogging due to their direct exposure to floor debris and spills, necessitating more regular cleaning and maintenance.

Let’s break down the key expense areas and provide an estimated cost comparison:

| Drain Type | Initial Installation Cost | Regular Maintenance (Yearly) | Emergency Repairs (Estimated) | Total Estimated 5-year cost (Example) |

|---|---|---|---|---|

| Hub Drain | Higher | Lower | Lower | Medium |

| Floor Drain | Lower | Higher | Potentially Higher | Higher |

Note: These are estimations and will vary significantly based on factors such as drain material, frequency of use, complexity of the installation, and professional maintenance schedules.

Key factors to consider include:

- Hub drains offer superior backflow protection, reducing the risk of contamination and potential health code violations.

- Floor drains often require more frequent cleaning to remove debris and prevent clogs.

- Regular maintenance is essential for both types of drains to prevent costly emergency repairs and operational disruptions.

- Hub drains generally have lower long-term maintenance needs due to their design and reduced susceptibility to clogging.

- Local plumbing codes and health regulations often influence drain selection and may mandate specific types of drainage systems in commercial kitchens.

Choosing the Right Drain: A Step-by-Step Guide

- Assess Kitchen Needs: Conduct a thorough evaluation of your kitchen’s size, layout, and specific drainage requirements. Identify high water volume food preparation areas, equipment locations, and potential sources of spills and wastewater.

- Check Local Codes: Research local plumbing codes and health regulations regarding backflow prevention, drainage requirements, and approved drain types for commercial kitchens.

- **

- Xbox 1 Games Not Loading? Try These Simple Troubleshooting Steps - February 23, 2026

- Xbox One Games Not Loading? Heres How to Fix It - February 22, 2026

- Fix Xbox Games Not Loading Issues on Your Console - February 21, 2026